Currently, there are different techniques of marking a PCB that are largely used in the industry. These technique contain stamps, ink markings, laser marketing and stickers technique, to mention a few techniques. Although, different producers use different techniques as they have different properties quality, cost and time of labeling.

Advantages of PCB laser marketing over sticker/chemical marking

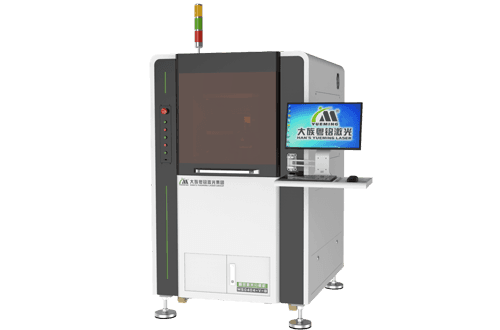

Let’s have a short look at the big advantages of using a Pcb Laser Marking Machine over other contemporary techniques of labeling.

Clarity of label

The end outcomes of PCB marking are substantially different for stickers/ink and laser markings. The sticker/ink marks are not extremely clear and can make problems during scanner or manual readings. On the other hand, the laser markings on PCBs make crystal clear markings that are simple to read by the naked eye and digital scanners.

Ease of use

Further, the PCB laser marking machines are very simple to use. The completely automated process helps you deal with the marking process like any other conveyor processing structure. The completely automated conveyor system makes it easy for you bulk-print your PCBs just by the click on a one key.

Time-saving

Inked marking or sticker marking of PCBs is a semi-auto to manual process which needs a big amount of manual labor and skill. In comparison, the laser marking of PCBs is a completely automated process that keeps time and labor and produces very efficient outcomes.

Affordable

Laser marking of PCBs cost substantially lower than the equal amount of labeling done by chemicals/ink. According to guesses, the bulk labeling of PCBs can cost $0.02 per marking with laser marking machine as matched to the $0.07 – 0.09 per marking cost with Ink labels.

Thus, PBC laser marking can substantially decrease the cost of labeling for PCB producers.

Environment-friendly marketing scheme

Most of the marking inks that are usually used for PCB markings are not atmosphere-friendly. As an outcome, it poses a grave risk to the atmosphere to mark PCBs using risky inks. Whereas, when you use the laser marking methodology for PCBs, you are making an atmosphere-friendly marking scheme.

The longevity of the marking

Ink stickers and markings tend to lose their illegibility over time. Thus, PCBs, that are older than a few years have markings that are difficult to read. Whereas, the laser marking is long-term and is still very clear after 10 to 15 years of use.

Thus, it is highly advised for the PCB producers to use laser marking methods for long-lasting markings.

Article Source: https://www.hansymlaser.com/news/advantages-of-pcb-laser-marking-machine

Media Contact

Company Name: Han’s Yueming Laser Group Co.,Ltd.

Contact Person: Media Relations

Email: Send Email

Phone: +86-769-22705851

Country: China

Website: https://www.hansymlaser.com/