As the world develops, the way we produce jewelry changes too. 3D printing has become a fast and efficient way to create jewelry designs and is embraced by jewelers around the world. Many companies have already started exploring the possibilities of 3D printed jewelry through various applications and manufacturing methods.

3D Printed Jewelry Chains: Meeting the Unique Needs of the Middle East and Southeast Asian Markets .

The jewelry industry has been enjoying a renaissance with the advent of 3D printing technology, which offers endless opportunities to create unique and innovative jewelry pieces. 3D printing has revolutionized the jewelry industry by offering significant benefits such as reduced time-to-market, lower tooling costs, and facilitated customization.

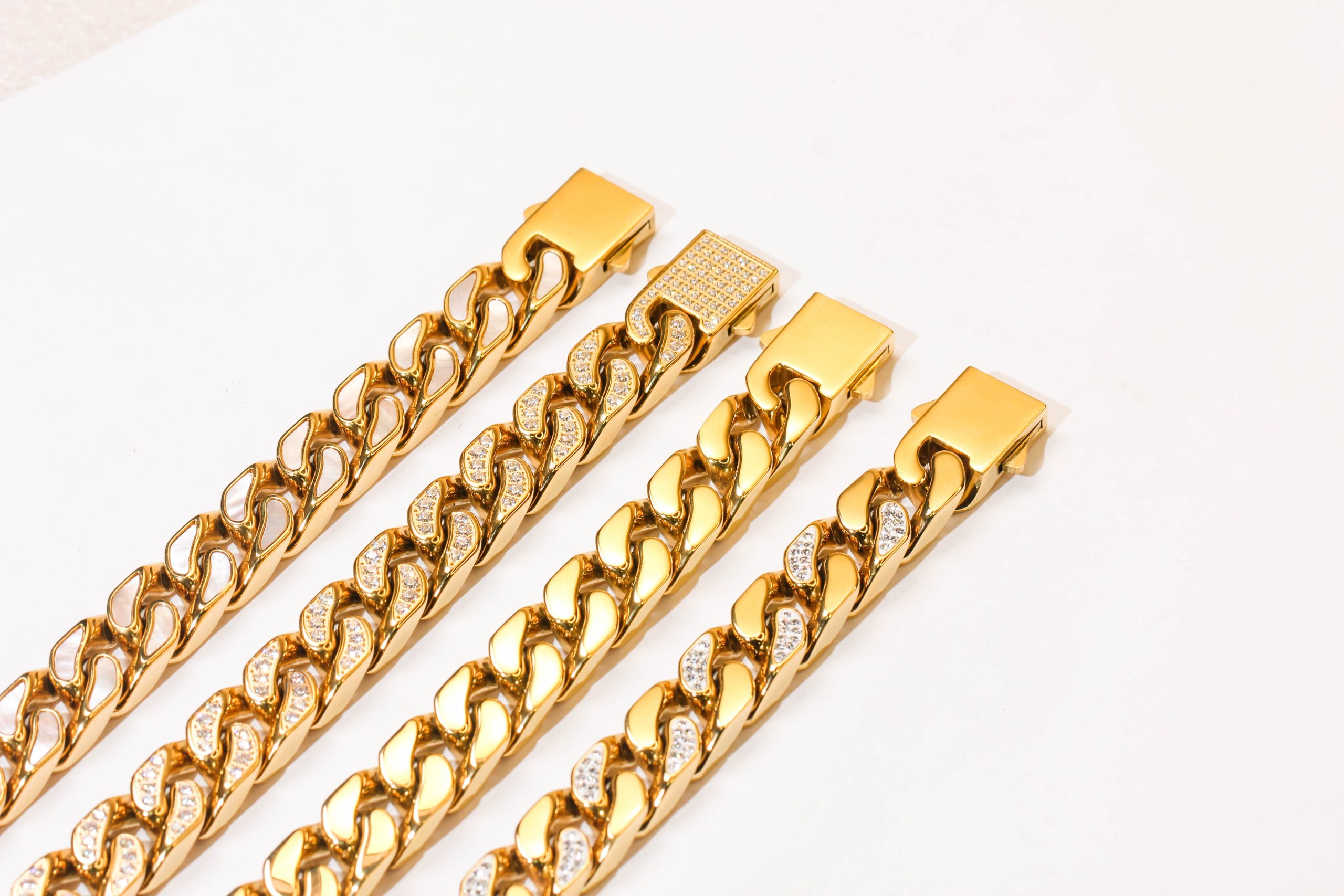

Jewelry chains are one of the hottest trends in the industry, and 3D printing is perfect for mass producing custom chains, especially to meet the unique needs of consumers in the Middle East and Southeast Asia.

The Middle Eastern market is known for high carat gold, bold designs, intricate patterns and a love of luxury jewellery. For example, a popular chain style in the region is the Figaro chain, which has a unique pattern of flat, circular links arranged in a specific order. 3D printing allows for the precise creation of intricate designs and shapes, making it easier to mass produce custom jewelry chains, such as the Figaro chain. 3D printing can also produce complex surface textures and patterns, which are especially useful for creating Middle Eastern-inspired chains with unique details.

In Southeast Asia, consumers prefer more elaborate, intricate chains with intricate designs and symbolism. Jewelry, especially gold chains, is often considered a long-term investment and a symbol of wealth and prosperity. Bismarck chains are popular in the region and are characterized by small overlapping links indicating a weak chain, but they can hold a lot of weight. 3D printing allows these chains with their intricate details to be replicated on a large scale while keeping costs low. The many available materials and finishes offered by 3D printing technology allow chains to be easily customized to suit different consumer preferences.

In summary, 3D printing offers jewelry manufacturers the ability to create custom, intricate and unique chains, which are in high demand in the Middle East and South East Asian markets. The technology provides a competitive advantage through faster production times, lower costs and diverse product variations that reflect the local trends and uniqueness of the region. By adopting 3D printing technology in the jewelry chain production process, jewelry manufacturers can meet market demand and increase their market share in the industry.

ifun has developed a jewelry printing resin specially designed for the 3D printing process. This resin has many unique properties that set it apart from other jewelry resins on the market. The resin has a wax content of 60%, is easy to cast, and has a fine and smooth surface. In addition, it can print even complex models with clear and accurate sharp corners.

Another great feature of ifun’s jewelry printing resin(iF800D) is its compatibility with LCD machines, a popular type of 3D printer used by many jewelry manufacturers. The resin weighs 45% less than common casting resins, making it easier to work with.

ifun’s 3D printing technology is also ideal for creating unique chain designs that are both beautiful and functional. Chain design can be extremely complex, with many intricate details to consider. Thanks to ifun’s technology, these designs can be printed easily and with the same level of quality as traditional casting methods.

Media Contact

Company Name: IFUN

Email: Send Email

Country: China

Website: https://ifun3d.com/