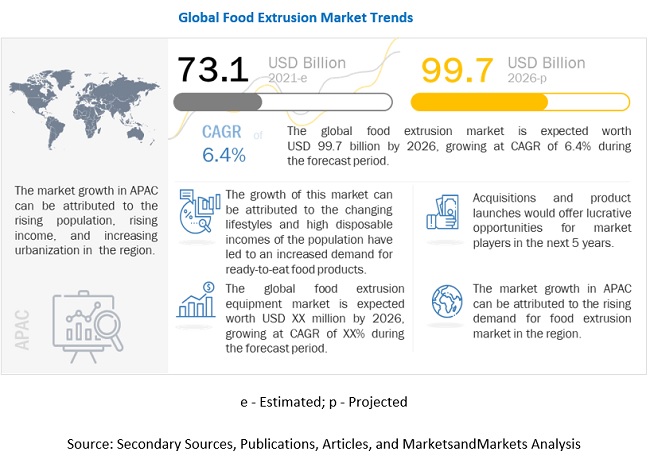

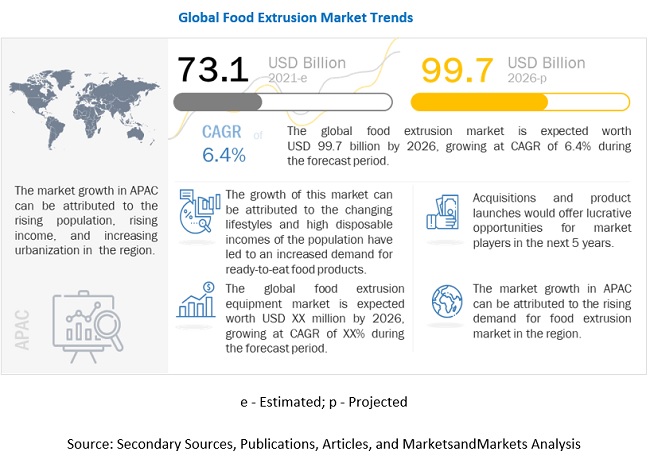

The global food extrusion market is estimated to be valued at USD 73.1 billion in 2021. It is projected to reach USD 99.7 billion by 2026, recording a CAGR of 6.4% during the forecast period. Innovative and flexibly designed processing and packaging systems are the prerequisites for manufacturers to keep pace with the trends in the food industry that may arise from operation cost and consumer spending. Advanced automated food processing equipment enables high-volume production of better-quality products with a longer shelf life.

Drivers: Increase in demand for processed product types

The food extrusion market is primarily driven by the growth of the processed food industry. The changing lifestyles and high disposable incomes of the population have led to an increased demand for ready-to-eat product types as they help save time and effort. Additionally, the demand for processed product types from the urban population of developing economies is expected to subsequently drive the demand for food extrusion equipment. The rising per capita income and the increasing trend of snacking between meals are also fueling the demand for extruded product types. Consumer preferences in emerging economies such as China, India, Brazil, and the Middle East have gradually transitioned from traditional homemade breakfasts and snacking meals to ready-to-eat products over the last couple of decades.

Download PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=221423108

Single screw extruder has uniform expansion of raw materials

A single screw extruder consists of a live bin, feeding screw, preconditioning cylinder, extruder barrel, die, and knife. It uses one single screw in the barrel of the extruder to transport and shape multiple ingredients into a uniform product type by forcing the ingredient mix through a shaped die to produce a uniform shape. Single screw extruders typically consist of three zones: feeding zone, kneading zone, and cooling zone. In contrast to twin screw extruders, single screw extruders have poor mixing ability, owing to which the materials are required to be pre-mixed or preconditioned.

The hot extrusion segment, by process type is projected to be the fastest-growing during the forecast period.

Hot extrusion or extrusion-cooking of raw food materials deal with the extrusion of ground material at baro-thermal conditions. With the help of the shear energy exerted by the rotating screw and additional heating of the barrel, the food material is heated to its melting point. In this process, the changed rheological status of the food is conveyed under high pressure through a die or a series of dies, and the product expands to its final shape. This results in very different physical and chemical properties of the extrudates compared to those of the raw materials used.

Speak to Analyst @ https://www.marketsandmarkets.com/speaktoanalystNew.asp?id=221423108

The European region dominated the food extrusion market.

The presence of a developed snack food market offers the European food extrusion market a prominent consumer base with opportunistic growth prospects. The growth of the food industry in this region is estimated to be driven by increasing consumption of processed product types in the Eastern & Southeastern European countries. Increasing consumption of snack product types in this region has also compelled manufacturers to source extruded snack products from other parts of the world for an uninterrupted supply of raw materials, as domestic production is not sufficient to meet the demand from the food industry of Europe.

The key service providers in this market include Bühler (Switzerland), Akron Tool & Die (US), Baker Perkins (UK), Coperion (Germany), GEA (Germany), KAHL Group (Germany), Triott Group (Netherlands), Flexicon (US), Groupe Legris Industries (Belgium), The Bonnot Company (US), American Extrusion International (US), Shandong Light M&E Co., Ltd (China), Snactek (India), Doering systems, inc. (US), PacMoore (US), Egan Food Technologies (US), Schaaf Technologie GmbH (Germany), Wenger Manufacturing, Inc. (US), Brabender GmbH & Co. KG (Germany), and Jinan Darin Machinery Co., Ltd., (China).

About MarketsandMarkets™

MarketsandMarkets™ provides quantified B2B research on 30,000 high growth niche opportunities/threats which will impact 70% to 80% of worldwide companies’ revenues. Currently servicing 7500 customers worldwide including 80% of global Fortune 1000 companies as clients. Almost 75,000 top officers across eight industries worldwide approach MarketsandMarkets™ for their painpoints around revenues decisions.

Our 850 fulltime analyst and SMEs at MarketsandMarkets™ are tracking global high growth markets following the “Growth Engagement Model – GEM”. The GEM aims at proactive collaboration with the clients to identify new opportunities, identify most important customers, write “Attack, avoid and defend” strategies, identify sources of incremental revenues for both the company and its competitors. MarketsandMarkets™ now coming up with 1,500 MicroQuadrants (Positioning top players across leaders, emerging companies, innovators, strategic players) annually in high growth emerging segments. MarketsandMarkets™ is determined to benefit more than 10,000 companies this year for their revenue planning and help them take their innovations/disruptions early to the market by providing them research ahead of the curve.

MarketsandMarkets’s flagship competitive intelligence and market research platform, “Knowledgestore” connects over 200,000 markets and entire value chains for deeper understanding of the unmet insights along with market sizing and forecasts of niche markets.

Media Contact

Company Name: MarketsandMarkets

Contact Person: Mr. Aashish Mehra

Email: Send Email

Phone: 18886006441

Address:630 Dundee Road Suite 430

City: Northbrook

State: IL 60062

Country: United States

Website: https://www.marketsandmarkets.com/Market-Reports/food-extrusion-market-221423108.html