Shrink label is very adaptable, plastic, metal, glass and other packaging containers can be decorated, shrink film sleeve label due to the combination of high quality patterns and distinctive modeling, more and more popular in the market. This paper describes the characteristics and advantages of contraction film label and material selection principle, the content for friends’ reference:

Shrinkable film set of labels is essentially belongs to the category of heat shrinkable film, is a plastic film or emerging labels printed on the plastic pipe, mainly including PE, PVC, PET, such as common type heat shrinkable film, because the shrinkable film set is a stretch orientation in the production process, and in the process of using heat shrinkage of thermoplastic plastic film. Therefore, before the design of the surface pattern, we should consider the horizontal and longitudinal shrinkage rate of the material, as well as the deformation error allowed in all directions of the decoration text after contraction, so as to ensure the accurate reduction of the pattern, text and bar code shrunk to the container.

01 Advantages

Shrink-wrap label is a film set label printed on plastic film or plastic tube. It has the following characteristics:

1) Shrink film sleeve label processing is convenient, packaging sealing, anti-pollution, good protection of goods;

2) The film cover is close to the goods, the package is compact, and can show the shape of the goods, so it is suitable for the irregular goods that are difficult to pack;

3) Shrink film sleeve label labeling, without the use of adhesive, and can obtain the same transparency as the glass;

4) Shrink-wrapped label can provide 360° decoration for the packaging container, and can print product information such as product description on the label, so that consumers can understand the product performance without opening the package;

5) The printing of the label of the shrink film sleeve belongs to the printing in the film (the text and picture are on the inside of the film sleeve), which can protect the impression and has better wear resistance.

02 Design essentials and material selection principles

The label design

The design of the decoration pattern on the film should be determined according to the thickness of the film. When designing the pattern, it is necessary to make clear the transverse and longitudinal shrinkage rate of the film, as well as the allowable shrinkage rate in each direction after packaging and the allowable deformation error of the decoration pattern after shrinkage, so as to ensure that the pattern and text after shrinkage can be accurately restored.

Film thickness and shrinkage

Materials used for shrinkable film cover labels should focus on three factors: environmental requirements, film thickness and shrinkage performance.

The thickness of the film is determined based on the field of application and cost factors of the label. Of course, price is not the decisive factor, as each film is unique and both the user and the label printer must be clear about the film and the process best suited to the material before signing on. In addition, the index required by the processing equipment and other process factors also directly affect the choice of thickness. It is usually required that the film thickness of the shrink-sleeve label is 30-70 μm, among which 40μm and 50μm are more commonly used.

In addition, the film shrinkage rate has certain requirements, and the lateral (TD) shrinkage rate is higher than the longitudinal (MD) shrinkage rate. The transverse shrinkage of common materials is 50% ~ 52% and 60% ~ 62%, and can reach 90% in special cases. Longitudinal shrinkage rate required in 6% ~ 8%. When making shrinkable film sleeve labels, materials with small longitudinal shrinkage should be selected as far as possible.

03 Film material

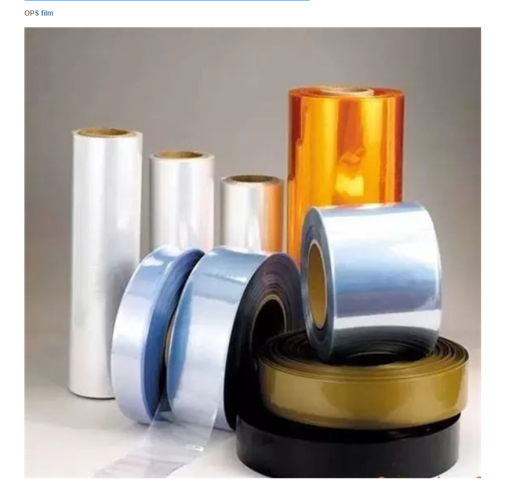

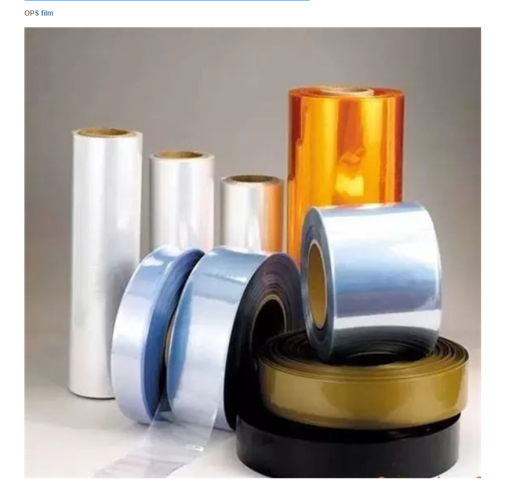

The materials for making the label of shrinkage film cover are PVC (PVC) film, pet (polyester) film, peg (modified polyester) film, ops (oriented polystyrene) film, etc. Its performance is as follows:

PVC film PVC

film is the most widely used film material at present. It is cheap, has a large temperature shrinkage range and is not high requirements for heat source. The main processing heat source is the combination of hot air, infrared light or both. However, PVC is difficult to recycle, when burning gas, which is not conducive to environmental protection, has been banned in Europe and Japan.

As a substitute for PVC films, OPS films have been widely used. Its shrinkage performance is good, also conducive to environmental protection. The domestic market of this product is in short supply, and at present, high-quality OPS mainly depends on import, which has become an important factor restricting its development.

PETG copolymer film is not only conducive to environmental protection, but also can adjust the shrinkage rate in advance. However, due to the excessive shrinkage, it will also be limited in use.

PET film

PET film is an internationally recognized environmental type thermal shrinkage film material. Its technical indicators, physical properties, application range and usage methods are close to PVC thermal shrinkage film, but it is cheaper than PETG, which is the most advanced unidirectional shrinkage film at present. Its transverse shrinkage rate is 70%, the longitudinal shrinkage rate is less than 3%, and it is non-toxic and pollution-free, which is the most ideal material to replace PVC.

04 Film cover label printing printing Printed on selected films.

At present, the printing of shrinkage film sleeve is mainly used in gravure printing, solvent printing ink, followed by flexible printing. With the development of flexo technology, printing color is bright and clear, can be comparable with gravure printing, with the thick and high gloss of gravure. In addition, flexo more use water-based ink, more conducive to environmental protection. Cutting with a high performance cutting machine will be used to cut the printed reel film material longitudinal cutting, and the edge part of the film will be processed to make it smooth, flat and not curly. When using a cutting machine, pay attention to avoid heat the blade, because the hot blade can cause the film to be cut to wrinkle. The suture of the film after longitudinal cutting is carried out by a suture machine, and the tube mouth is bonded to form the membrane sleeve required for packaging. The material margin required for suture depends on the accuracy of suture and the skill of the operator. The maximum recommended amount of suture is 10mm, usually 6mm. Transverse cutting and wrapping the film cover outside the commodity, and cutting the film horizontally according to its packaging size. At appropriate heating temperature, the length and width of the shrinkage film will shrink sharply (15% ~ 60%). Generally, the film size is required to be about 10% larger than the maximum size of the product shape. Heat shrinkage is heated by a hot passage, a hot oven, or a hot air spray gun. At this point, the shrink label will quickly shrink along the outer contour of the container, tightly fit with the outer contour of the container, forming a label protective layer that is completely consistent with the shape of the container. In the production process of shrinkage film sleeve label, it is necessary to carry out strict detection of each process through a special detection machine to ensure the production accuracy. The applicable scope of shrink label is very adaptable, can be used for the surface decoration, decoration of wood, paper, metal, glass, ceramics and other packaging containers, widely used in food, daily chemical products, chemical products packaging and decoration, such as various drinks, cosmetics, children’s food, coffee and so on.

Original Source: https://www.fzhgp.com/news/the-characteristics-and-advantages-of-shrink-film-label-and-the-principle-of-material-selection/

Media Contact

Company Name: Fuzhou Huaguang Color Printing Co., Ltd.

Email: Send Email

Phone: 0086-15606999155

Address:Building 4, No. 20, Zhaoyu Road, Gaishan Town

City: Fuzhou

State: Fujian

Country: China

Website: https://www.fzhgcp.com/