In recent years, the market for rental LED screens has become increasingly active. People have higher and higher requirements for ultra-high-definition dis-play and high flatness of LED screen. However, the traditional SMD technology has been unable to meet these requirements, which has prompted LED display manufacturers to make corresponding improvements in the surface treatment of the screen. There are mainly two technologies: AOB and GOB, to cope with the limitations of traditional LED packaging technology. GOB technology now has been widely used in rental LED displays, which not only improves the protection level, but also brings customers superior visual and tactile experience.

What are AOB and GOB technologies?

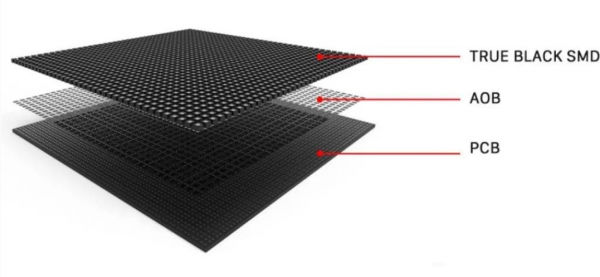

AOB is a packaging technology that is a nano-level surface coating process that can increase the strength of the LED lamps on the PCB, enhance the waterproof and dustproof performance of the screen, expand the viewing angle of the screen and enhance the color contrast. AOB technology mainly includes the filling layer and surface protection layer. The filling layer improves the ink color of the printed circuit board and the optical effect of the lamp surface to achieve a wide viewing angle. The surface protection layer prevents the lamp bead pins from being invaded by water vapor and dust.

GOB is the abbreviation of Glue on Board, which is another surface coating process, similar to the surface gluing process of outdoor LED displays. The surface of the SMD lamp board is filled with a layer of transparent epoxy resin, and the thickness of the lamp coating surface is up to 2~5mm, which has the effect of dustproof and waterproof. This is a technology to solve the LED lamp protection. The material not only has ultra-high transparency but also has ultra-strong thermal conductivity. It can adapt to any harsh environment and really achieve the functions like moisture proof, waterproof, dustproof, anti-impact, and anti-UV, avoiding the phenomena like a large area of dead light, drop light, etc. It is mostly used in the rental LED display market and indoor small-pitch LED display market.

The whole production process of GOB series products has about 3 steps:

1. Choose the best materials, LED lamps, high refresh rate driving ICs, and high-quality LED chips.

2. After the product is assembled, aging 72 hours for the inspection of lamp before GOB gluing.

3. After GOB gluing, aging for another 24 hours to reconfirm the product quality.

GOB technology is an innovative sealing method using epoxy membrane on the surface of the module. Different from AOB technology, GOB technology protects the screen by isolating the LED lamps from water, dust, and collisions, so that the LED lamps will not be damaged even in the presence of water and dust, while AOB technology prevents screen from damage by strengthening the connection between LED lamps and PCB boards.

2. The Integration of GOB Technology and Rental LED Screen in Eachinled

When GOB technology blends into rental LED screens, it will not only effectively avoid damages like falling LED lamps, dead pixels caused by harsh handling in daily use, but also improve the service time of the screens greatly.

After learning the real needs of stage rental screen applicaton, P1.56,P1.875, P2.6 and P2.9 of of Eachinled are borned and soon won the welcome in rental market. There are 4 “L” shape supporting feet on the edges of the panel and 2 curve locks available at both sides for possible needs of our clients. What’s worth notice, additional cover of GOB technology gives our LED rental screens characteristics like light and thin, easy to setup and dispart, free to scratches, etc. Both the cabinet design and product quality win the favor of our clients.

Media Contact

Company Name: EACHINLED

Email: Send Email

Phone: 0086-139-6855-3710

Address:602, 6th Floor, B3 Bld, Yijing Industrial Park, #3055 SongBai Road, Guangming Dist.

City: Shenzhen, 518000

Country: China

Website: https://www.eachinled.tech/