The accuracy of linear guides also varies, such as in the machine tool industry, where the precision required for the workpiece being processed is relatively high,Therefore, precision grade linear guides with H-grade or higher are generally chosen, while the automation industry only needs to play a role in transmission The requirements for function and accuracy are not high, and generally N level (ordinary level) is commonly used.

The first step in selecting a linear guide rail is to Check the weight and size of the workbench to calculate the approximate model and length of the guide rail to be used,With the approximate model and length, the next step is to confirm the installation size of the slider. Commonly used sliders include flange type and square type Type, and these two forms are divided into ordinary and extended. If the load-bearing capacity is large, it is recommended to choose an extended slider,

How to solve and prevent rust on linear guide rails if they rust

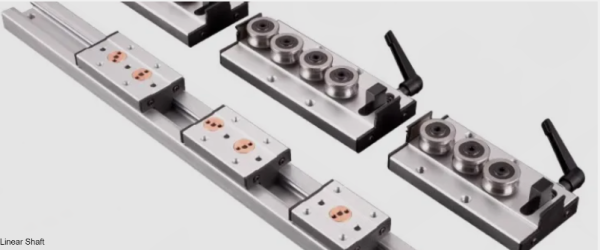

As one of the core components of equipment, linear guide rails and linear shafts serve as guiding and supporting functions. In order to ensure high machining accuracy of the machine, it is required that its guide rails and straight lines have high guiding accuracy and good motion stability.

During the operation of the equipment, a large amount of corrosive dust and smoke are generated during the processing of the processed parts. These smoke and dust accumulate on the surface of the guide rail and linear axis for a long time, which has a significant impact on the machining accuracy of the equipment,

And it will form corrosion spots on the surface of the linear axis of the guide rail, shortening the service life of the equipment. In order to ensure the normal and stable operation of the machine and the processing quality of the product, it is necessary to carefully carry out daily maintenance of the guide rail and linear shaft.

Please prepare a dry cotton cloth and lubricating oil for cleaning the guide rail. For example, the guide rails of a carving machine are divided into linear guide rails and roller guide rails. Cleaning of the linear guide rail: First, move the laser head to the far right (or left) and locate the linear guide rail,

Wipe with a dry cotton cloth until it is shiny and dust-free, then add a little lubricating oil (sewing machine oil can be used, do not use engine oil). Slowly push the laser head left and right a few times to evenly distribute the lubricating oil.

Cleaning of linear guide rail

Move the crossbeam to the inside, open the end covers on both sides of the machine, find the guide rail, use a dry cotton cloth to wipe the contact area between the guide rails and the rollers on both sides clean, then move the crossbeam to clean the remaining area clean.

How to prevent rust

The main reason why linear guides rust is due to our insufficient understanding of them. Normally, before leaving the factory, the surface of linear guides needs to be wiped with rust proof oil,

However, after using it for a period of time, it will still experience severe rusting.

After finishing the use of the linear guide rail, we need to apply rust proof oil on its surface again, which is very important for rust prevention. Although it should have been applied before leaving the factory, during use,

Evaporation will definitely occur over time, and rusting is inevitable.

After applying rust proof oil to the linear guide rail, it should be placed in a warehouse at room temperature and should not be mixed with corrosive objects, nor should it be temporarily unused,

Directly stored on the ground of the warehouse, as the ground will accelerate the evaporation of rust proof oil, this requires everyone to pay more attention when using.

ZLV has been specializing in the production of linear guide rails for 25 years

How to detect problems in the use of linear guides in advance

Linear guides can perform reciprocating linear motion in a given direction. If determined by their conflict nature, they can be divided into sliding conflict guides, rolling conflict guides, elastic conflict guides, and so on.

Usually, adverse situations may occur during operation.

Especially for some domestically produced guide rails with large clearances, the guide rails will swing to the side, resulting in poor noise between the sliders. Therefore, technicians must detect the “fault signal” of the linear guide rail bearings

Maintain high vigilance and preferably use auditory recognition to identify it.

With the increasing demand in the linear guide rail market, many advanced products have emerged in China, and their demand is also constantly increasing. It is necessary to avoid problems with the linear guide rail during operation. However, regular operation is required to avoid rust on the linear guide rail and apply high-quality mineral oil before proceeding with the operation

How to prevent dust on linear guide rails

1、 Special telescopic dust cover

In harsh environments, some models are equipped with dedicated soft retractable dust covers and dedicated dust covers. For detailed information and instructions on sealing gasket markings, please refer to the corresponding optional accessories (dust prevention) items for various products.

In addition, when used in environments prone to the effects of cutting chips and cutting fluid splashing, it is recommended to use a soft circular telescopic cover to protect the entire system, or use a large telescopic dust cover

2、 Special sealing gasket for linear motion system

To improve dust resistance, special synthetic rubber sealing gaskets with high wear resistance, as well as accessories such as stacked contact scrapers and cleaning rings, are prepared in each linear guide rail system.

Media Contact

Company Name: Zhejiang Shengben Bearing Manufacturing Co., Ltd.

Email: Send Email

Address:256 Shiniu Road

City: Lishui City

State: Zhejiang

Country: China

Website: https://shengbenzhejiangchina.com/