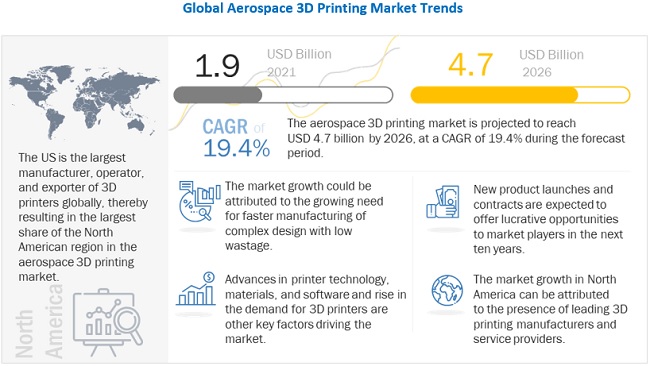

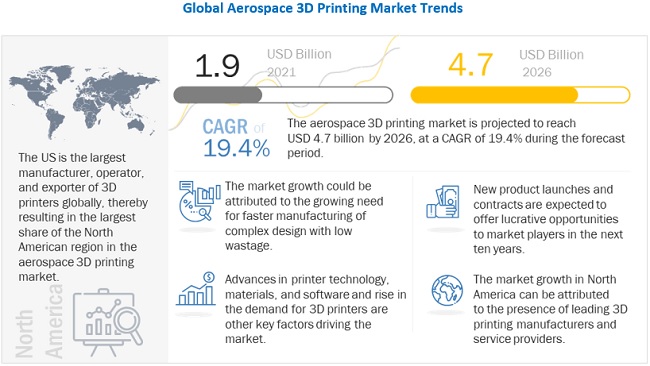

The report “Aerospace 3D Printing Market by Offerings(Printers, Materials, Services, Software), Technology, Platform(Aircraft, UAVs, Spacecraft), Application(Prototyping, Tooling, Functional Parts), End Product, End User(OEM, MRO), & Region – Global Forecast to 2026″, is estimated to be USD 1.9 billion in 2021 and is projected to reach USD 4.7 billion by 2026, at a CAGR of 19.4% during the forecast period. The demand for aerospace 3D printing is projected to be driven by the low volume production of aircraft components in the aerospace industry, rising demand for lightweight components, the need to reduce the production time of components, and the requirement for cost-efficient and sustainable products. The requirement for rapid prototyping is expected to fuel the growth of the aerospace 3D printing market during the forecast period.

• Informational PDF Brochure :- https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=7890041

Browse 182 market data Tables and 53 Figures spread through 233 Pages and in-depth TOC on “Aerospace 3D Printing Market by Offerings End User(OEM, MRO), & Region – Global Forecast to 2026″View detailed Table of Content here – https://www.marketsandmarkets.com/Market-Reports/aerospace-3d-printing-market-7890041.html

The major players in the aerospace 3D printing market include Stratasys Ltd. (U.S.), 3D Systems Corporation (U.S.), EOS GmbH (Germany), Norsk Titanium AS (Norway), Ultimaker B.V. (Netherlands), and EnvisionTec GmbH (Germany), These players have spread their business across various countries includes North America, Europe, Asia Pacific, Middle East, Africa, and Latin America. COVID-19 has impacted their businesses as well.

COVID-19 has affected almost every industry, especially aerospace. The immediate drop in the demand to manufacture aircraft and disruptions in raw materials have adversely affected the industry. Limitations in cross-border movements, disruptions in manufacturing and transportation, constrained supply chains triggering supply delays, and massive slowdowns in production over the first quarter of 2020 have also affected the industry.

In commercial aviation, companies are experiencing disruptions in production and a slump in demand due to the lack of laborers, less travel by passengers, and customers postponing the delivery of new aircraft. Demand for spare parts is also down as less maintenance is required. According to the Boeing 2019 Q2 report, the revenues for the first half (H1) 2019 vs. H1 2018 were down 19% and commercial aircraft deliveries for the same time were down 37%.

The need for cost-efficient custom printing and manufacturing would be one of the factors leading to the growth of the offerings segment.

The printer segment is expected to dominate the segment in the initial years of the forecasted period. The service segment is expected to lead the market by 2026 over the printer segment. The need for cost-efficient custom printing and manufacturing would be one of the factors leading to the growth of the segment. Most companies would outsource additively manufactured parts to 3D printing companies and need extensive after-sales service once the demand for 3D printed parts increases. These factors would lead to the growth of the service segment in the market.

The Material Extrusion or Fusion Deposition Modeling (FDM) segment is projected to witness the highest CAGR during the forecast period.

Based on technology, the Material Extrusion or Fusion Deposition Modeling (FDM) segment is expected to dominate the aerospace 3D printing market The extrusion process is fast and efficient at producing large volumes of continuous shapes in varying lengths with minimum wastage. The ability to manufacture complex shapes with varying thickness, textures, and colors is a major advantage of this process.

The Aircraft Segment is projected to witness the highest CAGR during the forecast period.

Based on platform, The aircraft segment is projected to dominate the aerospace 3D printing market, by platform, during the forecast period. The maximum number of developments would occur on an aircraft. The need for lightweight, cost-efficient aircraft and the need for fast manufacturing of complex parts would drive the adoption of 3D printers in aircraft manufacturing.

The engine component segment is projected to witness the highest market share during the forecast period

Based on the end products, the engine components segment is witnessing the highest market share for the aerospace 3D printing market during the forecast period. Ease of designing, improved strength, lightweight, and durability of the components manufactured, as well as their cost-effectiveness, contribute to the growth of end products

The functional parts is projected to witness the highest CAGR during the forecast period

Based on application, The prototyping segment is projected to lead the aerospace 3D printing market from 2021 to 2026. However, the functional parts segment is expected to grow at the largest CAGR during the forecast period. The growth of the functional parts segment can be attributed to the advancements in 3D printing technology and the increasing adoption of 3D printers into manufacturing processes across industries.

The North American market is projected to contribute the largest share from 2021 to 2026

The North American region is estimated to account for the largest share of 47.7% of the global aerospace 3D printing market in 2021. It is projected to record a CAGR of 18.6% during the forecast period, driven by the increasing adoption of 3D printing technology for manufacturing complex 3D components that are light in weight. Moreover, manufacturers of aircraft components and aircraft are switching to 3D printing technology to produce low-volume parts, thus fueling the growth of the aerospace 3D printing market.

About MarketsandMarkets™

MarketsandMarkets™ provides quantified B2B research on 30,000 high growth niche opportunities/threats which will impact 70% to 80% of worldwide companies’ revenues. Currently servicing 7500 customers worldwide including 80% of global Fortune 1000 companies as clients. Almost 75,000 top officers across eight industries worldwide approach MarketsandMarkets™ for their painpoints around revenues decisions.

Our 850 fulltime analyst and SMEs at MarketsandMarkets™ are tracking global high growth markets following the “Growth Engagement Model – GEM”. The GEM aims at proactive collaboration with the clients to identify new opportunities, identify most important customers, write “Attack, avoid and defend” strategies, identify sources of incremental revenues for both the company and its competitors. MarketsandMarkets™ now coming up with 1,500 MicroQuadrants (Positioning top players across leaders, emerging companies, innovators, strategic players) annually in high growth emerging segments. MarketsandMarkets™ is determined to benefit more than 10,000 companies this year for their revenue planning and help them take their innovations/disruptions early to the market by providing them research ahead of the curve.

MarketsandMarkets’s flagship competitive intelligence and market research platform, “Knowledgestore” connects over 200,000 markets and entire value chains for deeper understanding of the unmet insights along with market sizing and forecasts of niche markets.

Media Contact

Company Name: Marketsandmarkets pvt ltd

Contact Person: Mr. Aashish Mehra

Email: Send Email

Phone: 18886006441

Address:630 Dundee Road Suite 430

City: Northbrook

State: IL 60062

Country: United States

Website: https://www.marketsandmarkets.com/Market-Reports/aerospace-3d-printing-market-7890041.html